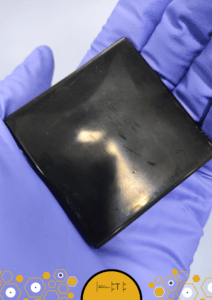

The CTC Technology Centre has produced polymer composite material designed specifically for the passive shielding of microelectronics from space radiation. By integrating a commercially available resin with metal oxides, researchers at the Cantabrian Centre have developed a material that not only possesses enhanced shielding capacities but also improved thermo-mechanical properties. This breakthrough could address broader radiation-related challenges, such as the protection of crew and structures.

Carla Ortiz, a technologist specialising in Advanced Materials and Nanomaterials, along with Luis Arriaga, deputy project manager at Alter, showcased these findings at ACCEDE – ESCCON 2025. Held in Seville, this event is the premier European forum on electrical, electronic, and electro-mechanical (EEE) components in space applications.

During the third session of this international congress, Ortiz and Arriaga highlighted the advancements in innovative formulations and the tests conducted to analyse material behaviour. Despite there having been more than one test, they presented results from radiation, viscosity, outgassing and thermo-mechanical properties shielding tests, which are vital for assessing the functionality of the materials.

The findings from tests on a commercially available resin are promising because they establish a solid foundation for customisable protection solutions that still have room for improvement. The knowledge and experience gained through this project are poised to facilitate the development of lightweight solutions that could address other radiation-related challenges in space, such as the protection of crew and structures. Furthermore, the methodology employed for the selection and characterisation of materials has been successfully developed and validated, proving applicable to various material combinations.

The SRPROTEC project, short for ‘Space Radiation Shielding in Microelectronics through the Development of Advanced Composite Materials’, which includes these developments, was initiated in response to the need to protect microelectronics in space. Space radiation, originating from galactic cosmic rays (GCR), solar energetic particles (SEPs) and particles trapped in the Van Allen belts, pose a significant risk of inducing errors in complex electronic devices. The effects of ionising radiation on space electronics are primarily categorised into two areas: total ionising dose (TID) and single event effects (SEE). TID refers to the long-term degradation of electronics due to the cumulative energy deposited on the material. Effects include parametric failures or variations in device parameters and functional failures. SEE occurs when a single ion strikes the material, depositing enough energy to disrupt device operation. Such events can significantly compromise the success of a space mission.

With 36 months of implementation, SRPROTEC is led by ALTER Technology, a provider of micro and optoelectronics services, with CTC as an expert partner for the technological side of the project. Additional tests (including mechanical, density, thermal and electrical conductivity, thermal shock and humidity assessments, among others) will enable the project team to characterise the most suitable materials for achieving their objectives. As the materials are in direct contact with the microelectronics they are designed to protect, there is a preference for materials with low electrical conductivity and a low coefficient of thermal expansion.

Once this milestone is reached, the project team will encapsulate real electronic components for testing to validate the material at the component level. They are intended to be compatible with “Dam&Fill” and “Potting’” encapsulation techniques. “Dam&Fill” involves a two-step process: first, a high-viscosity material is applied to create a barrier around the components; then, a filler material is added to cover the components. The “Potting” technique involves immersing the component in a liquid material, which, when solidified, forms a protective shield.

The SRPROTEC initiative is one of three research projects in which CTC is directly involved in the space sector. In this sense, the project will provide the centre with new capabilities that will improve and enhance its services to companies linked to this field, which has potential for the nuclear industry or medicine.

This project also allows CTC to continue to expand its knowledge in composite materials and increase its specialisation in the development of nanocomposites, one of the technology centre’s main lines of work.

The Ministry of Science and Innovation funds SRPROTEC through the Public-Private Partnership 2021 Call for Projects. This funding is part of strategic action number 4 of the Spanish Government’s National R&D Programme, which focuses on ‘Digital World, Industry, Space and Defence’. Specifically, the initiative falls under the action line ‘New materials and manufacturing techniques’.