The CTC Technology Centre has developed an innovative method to characterise the degradation process of lithium-ion batteries used in the special sector. This breakthrough integrates a range of predictive tools powered by artificial intelligence to forecast the specific charge cycle at which each battery is likely to fail. It is a highly promising system that enhances the reliability of these components prior to launch, minimises operational risks and enables the adoption of more modern and efficient technologies within the industry’s value chain, without being constrained by outdated validation procedures.

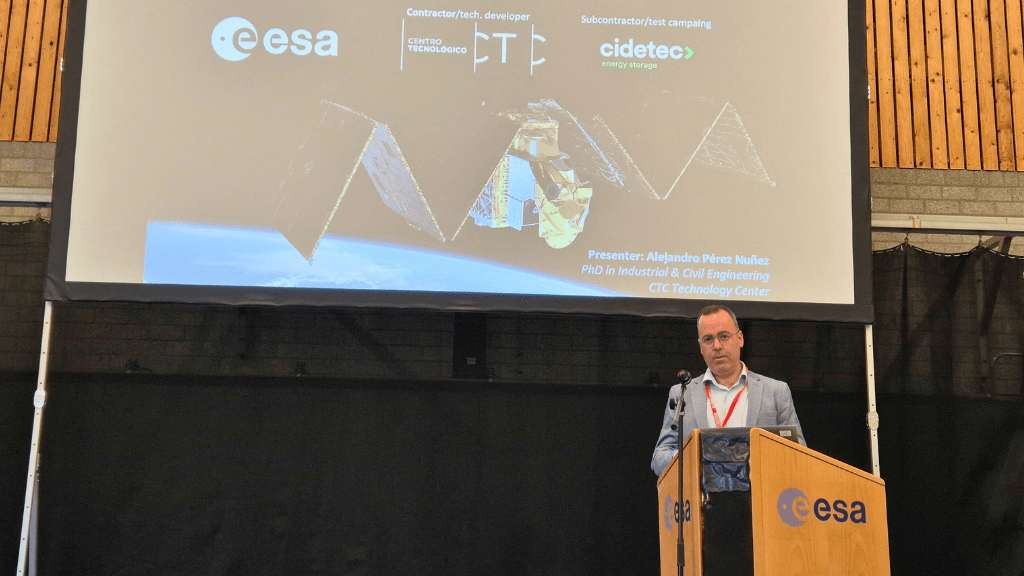

Dr Alejandro Pérez, European Project Manager at CTC, presented the details of this research during the ‘ESA Power Workshop 2025’, a three-day event held at ESTEC (ESA’s European Space Research and Technology Centre), which explored key developments shaping the future of the European space sector.

Entitled ‘New Methodology for Accelerated Assessment of Battery Cell Performances’, the presentation addressed one of the main technological challenges facing the industry. Currently, qualifying a battery for a space mission can take up to seven years, whereas in other sectors, such as the automotive industry, this process is completed in just a few months. This significant disparity hinders innovation and poses a risk to the fast-paced space race, in which agencies worldwide must accelerate the development of power systems in order to remain competitive.

After many months of analysing current research, technologies and regulations related to lithium battery testing, CTC has developed an innovative method to characterise degradation processes across various test types much more rapidly. CIDETEC conducted the experimental campaign that enabled CTC to validate and finalise the development of the aforementioned technologies.

Electrochemical cells are the active core of battery systems, the components that convert chemical energy into electrical current. To assess their durability and efficiency, accelerated tests and evaluations are carried out to analyse their performance under various stress conditions. These tests also enable the measurement of each cell’s response to different load levels, and with these parameters, their expected service life can be determined.

Once the method has been tested and validated, the model is completed with two artificial intelligence tools designed to predict the outcome of the experiments. Specifically, during cyclic testing for battery validation, these tools can anticipate the exact cycle at which each battery is likely to fail. The system also incorporates software capable of characterising and evaluating battery ageing mechanisms, as well as determining their relative impact over the battery’s lifespan, which significantly reduces the time required for experimentation and accelerates the overall testing process.

The methodology presented offers a threefold benefit. For the European Space Agency, it serves as an innovative tool and a key asset in aligning its developments with the rapidly evolving international space economy.

For the battery industry, it opens the door to faster and more predictive performance assessment; a breakthrough applicable not only to the space sector, but also to industries such as automotive, aeronautics and energy, where batteries are also required to operate under extreme conditions. Finally, as previously noted, progress in this field enables Europe to take a significant step forward in the global space race.