Anticipating the progression of atmospheric corrosion in critical metal infrastructures is one of the major challenges faced by industrial sectors such as energy, transport and construction. In response to this situation, the MACIC project will develop and validate a multimodal sensor that will combine physical and electrochemical monitoring technologies with advanced artificial intelligence models to track the evolution of this phenomenon. This comprehensive and innovative solution has emerged as a response to a problem that entails an annual economic impact of 300 billion euros in the European Union.

The CTC Technology Centre is one of the three entities participating in this research, which has a budget of 456.213 euros funded under the 2024 Public-Private Collaboration Projects Call. The engineering company CHATU TECH is leading and coordinating a consortium completed by the Asturian technology centre IDONIAL, with which it will work jointly over the next 36 months.

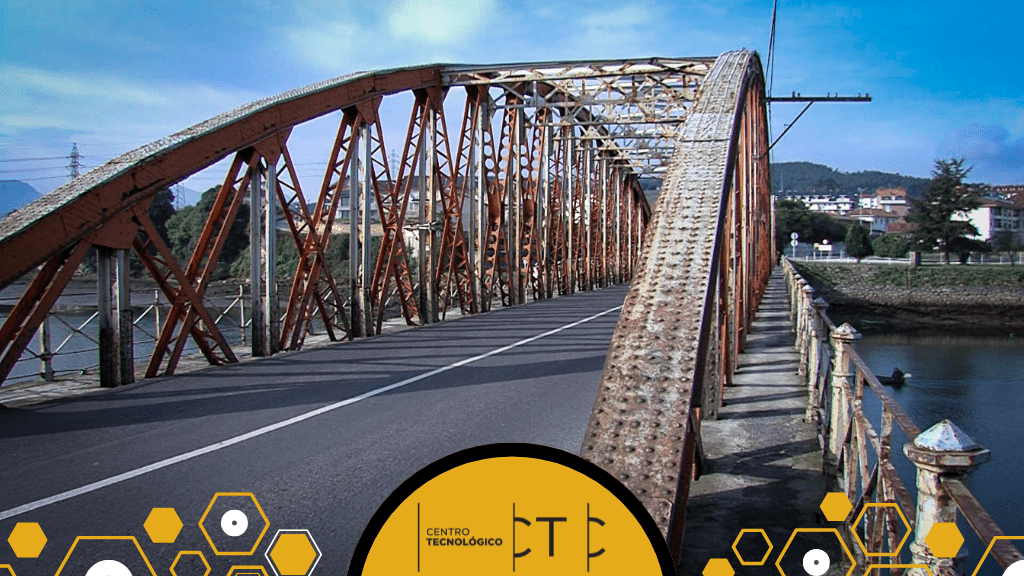

The MACIC project (Advanced Corrosion Monitoring for Critical Infrastructure) introduces a series of key innovations that will transform the preventive maintenance of metal installations such as bridges, refineries and communication towers. Indeed, integrating multiple advanced technologies will enable a comprehensive approach to optimising the performance and service life of these structures.

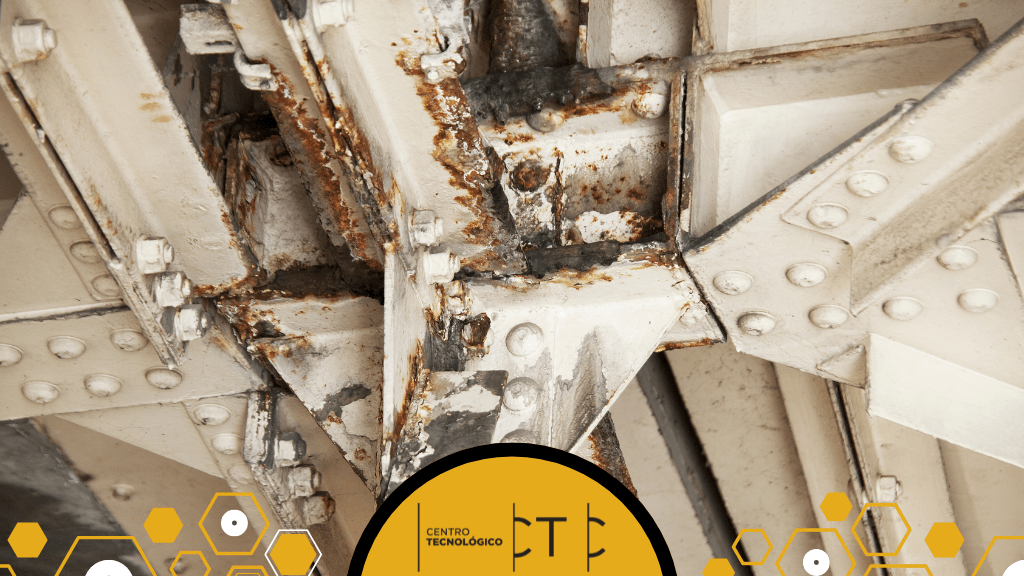

First, a multimodal monitoring sensor will be developed to provide an accurate, real-time assessment of the condition of the material. In addition, its customised modular design will allow the sensor to be tailored to the specific needs of each environment, ensuring its versatility and ease of integration across multiple configurations.

Real-time data acquisition will also enable the early detection of structural failures and the optimisation of maintenance strategies. Finally, MACIC will incorporate predictive models based on artificial intelligence that accurately analyse collected data to anticipate corrosion progression, support proactive decision-making, and significantly enhance the efficiency and safety of the monitored infrastructure.

The project, funded by the Ministry of Science, Innovation and Universities, the State Research Agency and the ERDF, is divided into six work packages. CTC will lead the two packages for field validation and the development of artificial intelligence-based algorithms to enhance the predictive capability of the system.

Specifically, the CTC team will install the prototype corrosion sensor in a relevant environment, namely a critical infrastructure, with the aim of validating its performance under real conditions. It will also integrate the data obtained with atmospheric parameters that influence corrosion. Validation under real operational conditions will enable optimising the accuracy of the multimodal sensor, improving the reliability of AI-based predictive models, and facilitating integration with maintenance management systems.

These data will enable CTC Team to develop artificial intelligence algorithms capable of predicting the atmospheric corrosion rate experienced by the sensor’s electrodes. To this end, two different approaches will be explored. On the one hand, an instantaneous prediction model will be developed, designed to estimate corrosion based solely on atmospheric parameters. On the other hand, a temporal prediction model will be implemented to anticipate future corrosion by accounting for historical data on both corrosion levels and environmental parameters.

At the start of the project, the Technology Readiness Level (TRL) of the MACIC solution stands at TRL 3-4, with the key concepts and initial tests validated in controlled environments. By the end of the project, MACIC aims to reach TRL 6, validating the core technologies in relevant environments and ensuring their readiness for future deployment in critical infrastructures.

Corrosion is one of the most significant challenges for industrial infrastructures and assets, with an estimated economic impact of 300 billion euros in the European Union, equivalent to 3.4% of Gross Domestic Product (GDP). In Spain, this percentage amounts to 44 billion euros in 2023. The implementation of effective management models, such as MACIC, could reduce this cost by 25% to 30% and significantly promote the development of the circular economy. In addition to markedly improving the safety and reliability of critical infrastructures, its application would reduce unnecessary repairs and optimise the recycling of metal materials.